Taiwan mhando Chinese mutengo MVP866 Machine centre

Saizi yekugadzira

| Model | Unit | MVP 866 |

| Tafura yebasa | ||

| Tafura saizi | mm(inch) | 950×600(38×24) |

| T-inogadzirisa saizi (inogadzirisa nhamba x widex kureba) | mm(inch) | 5×18×110(0.2×0.7×4.4) |

| Maximum load | Makirogiramu (lbs) | 600(1322.8) |

| Travel | ||

| X-axis kufamba | mm(inch) | 800(32) |

| Y-axis kufamba | mm(inch) | 600(24) |

| Z-axis kufamba | mm(inch) | 600(25) |

| Distance from Spindle nose to table | mm(inch) | 120-720(4.8-28.8) |

| Distance from spindle center to column surface | mm(inch) | 665(26.6) |

| Spindle | ||

| Spindle taper | type | BT40 |

| Spindle Speeds | rpm | 10000/12000/15000 |

| Drive | type | Belt-tvpe/Zvakananga zvakabatanidzwa/Directlv zvakabatanidzwa |

| Feed rate | ||

| Kucheka chiyero chekudya | m/min(inch/min) | 10(393.7) |

| Inokurumidza pa(X/Y/Z) matemo | m/min(inch/min) | 36/36/30(48/48/36) |

| (X/Y/Z) inokurumidza kufamba | m/min(inch/min) | 1417.3/1417.3/1181.1 (1889.8/1889.8/1417.3) |

| Otomatiki chishandiso chekuchinja system | ||

| Tool Type | type | BT40 |

| Tool kugona | set | Arm 24T |

| Maximum tool dhayamita | m(inch) | 80(3.1) |

| Maximum tool kureba | m(inch) | 300(11.8) |

| Maximum tool uremu | kg(lbs) | 7(15.4) |

| Tool to tool shanduko | sec | 3 |

| Motor | ||

| Spindle drive mota Kuenderera mberi kushanda / 30 min yakayerwa | (kw/hp) | MITSUBISH 5.5/7.5 (7.4/10.1) |

| Servo drive mota X, Y, Z axis | (kw/hp) | 2.0/2.0/3.0 (2.7/2.7/4) |

| Machine pasi nzvimbo uye uremu | ||

| Nzvimbo yepasi | mm(inch) | 3400×2500×3000 (106.3×98.4×118.1) |

| Kurema | kg(lbs) | 7000(15432.4) |

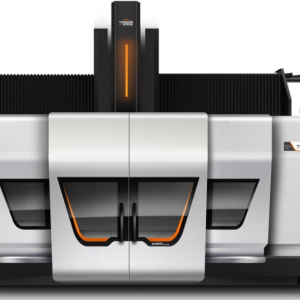

Machine Center

Yepamusoro-inomhanya yakakwira-chaiyo vertical machining centre inotora kunze kwenyika kudzora masisitimu akadai seMitsubishi neFanuc uye ayo anotsigira servo madhiraivha nemamotor kuona matatu-axis kana akawanda-axis yekubatanidza. Inokodzera zvimiro zvakaomarara, maitiro akawanda, yakanyanya kurongeka zvinodiwa, uye akawanda kuisirwa Kusunga chete uye kugadzirisa kunogona kupedzisa kugadzirisa kwezvikamu zvakagadziriswa. Iyo machining Center inogona kugadzirisa makabati, yakaoma yakakombama nzvimbo, yakaumbwa zvikamu, mahwendefa, maoko, uye maplate zvikamu, uye inoshandiswa zvakanyanya munzvimbo yeaerospace, mota dzemotokari, zvishandiso, machira akareruka emaindasitiri, midziyo yemagetsi, uye kugadzira michina.

Yese muchina chimiro

Nhengo dzemuviri dzakagadzirwa nemhando yepamusoro FC300 brand cast iron, iyo yekusimbisa yemukati inosimbiswa, ese anochembera echisikigo, chipiri kutsamwa uye vibration kurapwa kuchembera, uye iyo inopera yekuongorora chinhu inoitwa kuburikidza neyakasarudzika dhizaini software. Iine simba guru, kugadzikana kwakanaka uye haisi nyore Deformation uye mamwe maitiro. Iyo yakakura-yakafara base dhizaini inoita kuti simba rose remuchina wekushandisa riwedzere yunifomu uye kushanda kwacho kugadzikana. Iyo yakakura-angled herringbone column structure inotora yakakwirira-density, yakakwirira-yakasimba-yakaita mupunga bhora mesh muchinjiko unosimbisa mbabvu kudzivirira zvinobudirira deformation uye vibration yekoromo. Iyo screw inotsigira inotakura chigaro inotora iyo yakakosha yekukanda dhizaini nemuviri wekukanda, uye workbench screw nati chigaro uye worktable inosanganiswa yekukanda dhizaini, iyo inovandudza zvakanyanya kusimba uye kugadzikana kwemuchina chishandiso panguva yekufamba. Chimiro chinonzwisisika, dhizaini yakasimba uye hunyanzvi hwekugadzira zvinobudirira hunoita kuti kuomarara kwemuchina wese uye kurongeka uye kugadzikana kwekushandisa kwenguva refu.

Main shaft

bhokisi-mhando ipfupi mhino yekupedzisira spindle musoro chimiro, yemukati mbabvu yekusimbisa, main shaft mota inosimudza chigaro uye bhokisi muviri unotora yakasanganiswa dhizaini dhizaini, kusimba kwakasimba, kubatwa kwakanaka kwekuvhunduka, kunyatso kudzikisa kuzunguzika uye resonance yeiyo huru shaft panguva yekushanda. Yakashongedzerwa neTaiwan yakakurumbira brand spindle, iyo spindle inotora kunze kwenyika super-chaiyo bevel bhora inotakura uye yakakura-span yekutsigira dhizaini, kuitira kuti spindle igone kumira yakasimba radial uye axial thrust uye kubvisa kuzunguzika kunokonzerwa nekurema kwekucheka. Iyo yakanyanya kumhanya yeiyo huru shaft ndeye 15000RPM, pamwe chete nekufambiswa kwegapless precision coupling, iyo ine hunhu hwehupamhi hwepamusoro, ruzha rushoma, kurasikirwa kwesimba shoma uye nekukurumidza kupindura. Iyo spindle mota servo inotora simba rekuti risimuke, iro rinonatsiridza zvakanyanya kumhanya kwekupindura kwemota kana yatanga. Iyo mhino ye spindle inotora akawanda-maze uye mhepo jira guruva dhizaini, iyo inogona kunyatso kudzivirira kupinda kwemarara uye kuve nechokwadi chekurongeka uye hupenyu hweiyo spindle yekushandiswa kwenguva refu.