CNC Mirror Spark Machine

Parameter tafura

Kugona parameter tafura

| Item | Unit | Value |

| Saizi Yetafura (Yakareba × Yakafara) | mm | 700×400 |

| Yemukati Dimension yeKugadzira Liquid Tangi (Yakareba × Yakafara × Yakakwirira) | mm | 1150×660×435 |

| Liquid Level Adjustment Range | mm | 110–300 |

| Yakanyanya Kukwanisa Kugadzira Liquid Tangi | l | 235 |

| X, Y, Z Axis Kufamba | mm | 450×350×300 |

| Maximum Electrode Weight | kg | 50 |

| Maximum Workpiece Saizi | mm | 900×600×300 |

| Maximum Workpiece Weight | kg | 400 |

| Zvinhambwe kusvika paMaximum Distance kubva Kushanda Tafura kusvika Electrode Head | mm | 330–600 |

| Positioning Accuracy (JIS Standard) | μm | 5 μm/100mm |

| Zvakadzokororwa Positioning Kururama (JIS Standard) | μm | 2 μm |

| Yese Dimension yeMuchina Chishandiso (Kureba × Upamhi × Kureba) | mm | 1400×1600×2340 |

| Machine Weight Approx. (Kureba × Kureba × Kureba) | kg | 2350 |

| Dimension Dimension (Kureba × Kufara × Kureba) | mm | 1560×1450×2300 |

| Reservoir Volume | l | 600 |

| Kusefa Nzira yeMachining Fluid | A | Exchangeable Pepa Core Sefa |

| Maximum Machining Current | kW | 50 |

| Total Input Power | kW | 9 |

| Input Voltage | V | 380V |

| Optimum Surface roughness (Ra) | μm | 0.1 μm |

| Minimum Electrode Kurasika | - | 0.10% |

| Standard Process | Mhangura / simbi, micro mhangura / simbi, graphite / simbi, simbi tungsten / simbi, micro copper tungsten / simbi, simbi / simbi, mhangura tungsten / yakaoma alloy, mhangura / aluminium, graphite / kupisa kusingachinji alloy, graphite / titanium, mhangura / mhangura | |

| Interpolation Method | Mutsetse wakatwasuka, arc, spiral, bamboo pfuti | |

| Various Compensations | Nhanho kukanganisa muripo uye gap muripo unoitwa kune yega axis | |

| Maximum Number of Control Axes | Three-axis three-linkage (yakajairwa), ina-akisi ina-inobatanidza (sarudzo) | |

| Various Resolutions | μm | 0.41 |

| Minimum Drive Unit | - | Bata skrini, U dhisiki |

| Input Method | - | RS-232 |

| Display Mode | - | 15 ″ LCD (TET * LCD) |

| Manual Control Bhokisi | - | Standard inching (yakawanda-level switching), yebetsero A0~A3 |

| Position Command Mode | - | Zvese zviri zviviri mhedziso uye kuwedzera |

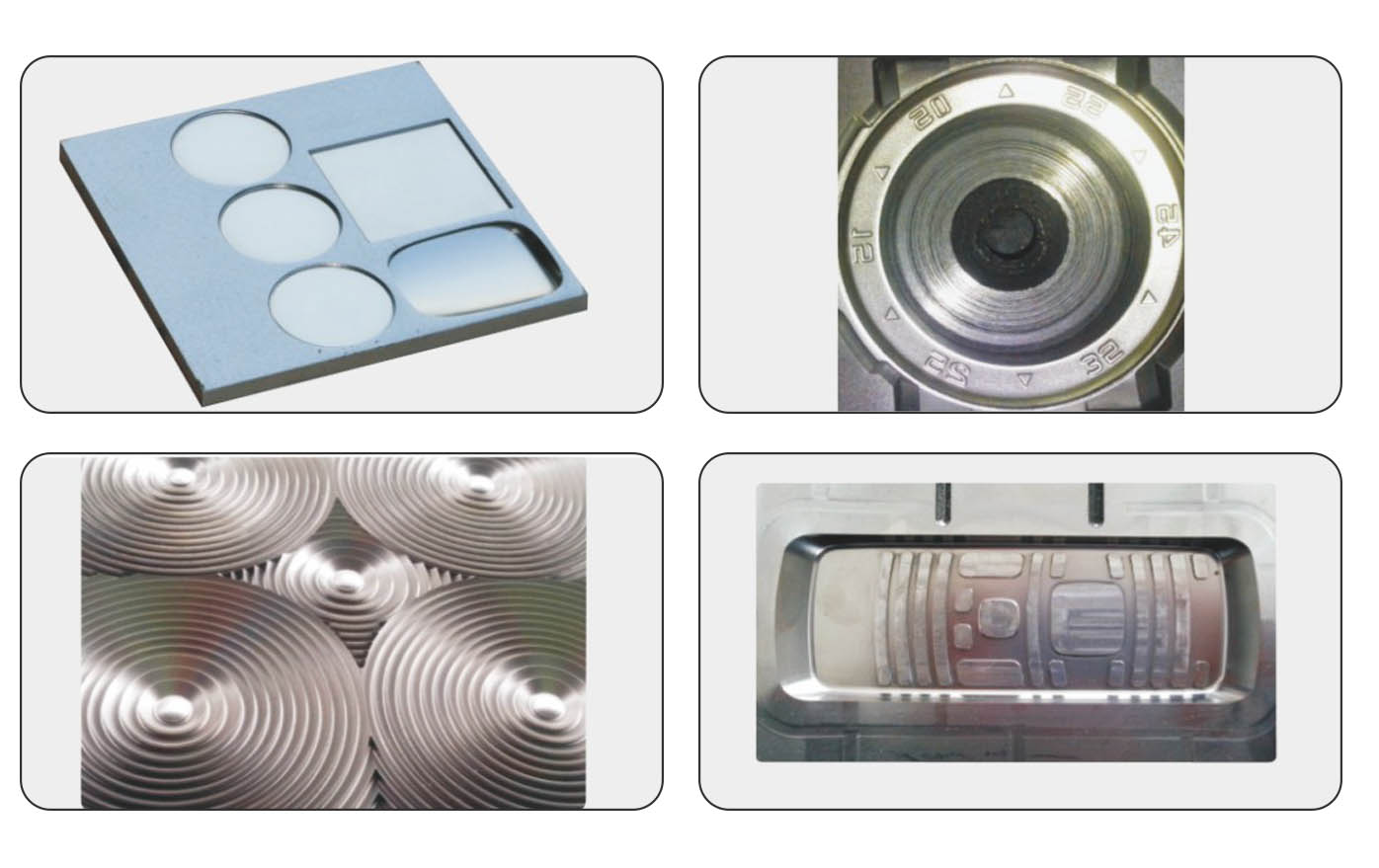

Muenzaniso Wesumo

Mienzaniso Yekugadzirisa Yakakwana (Mirror Finish)

| Muenzaniso | Machine Model | Material | Size | Kukasharara Kwepamusoro | Processing Hunhu | Processing Nguva |

| Mirror Finish | A45 | Mhangura – S136 (Inobva kunze) | 30 x 40 mm (Curved Sample) | Ra ≤ 0.4 μm | Kuoma Kwakakwirira, Kubwinya Kwepamusoro | 5 maawa 30 maminitsi (Curved Sample) |

Watch Case Mold

| Muenzaniso | Machine Model | Material | Size | Kukasharara Kwepamusoro | Processing Hunhu | Processing Nguva |

| Watch Case Mold | A45 | Mhangura – S136 Yakaomeswa | 40 x 40 mm | Ra ≤ 1.6 μm | Uniform Texture | 4 maawa |

Razor Blade Mold

| Muenzaniso | Machine Model | Material | Size | Kukasharara Kwepamusoro | Processing Hunhu | Processing Nguva |

| Razor Blade Mold | A45 | Mhangura – NAK80 | 50 x 50 mm | Ra ≤ 0.4 μm | Kuoma Kwakakwirira, Kuumbwa KweUniform | 7 maawa |

Foni Case Mold (Mixed Powder Processing)

| Muenzaniso | Machine Model | Material | Size | Kukasharara Kwepamusoro | Processing Hunhu | Processing Nguva |

| Nhare Nyaya Mold | A45 | Mhangura – NAK80 | 130 x 60 mm | Ra ≤ 0.6 μm | Kuoma Kwakakwirira, Kuumbwa KweUniform | 8 maawa |

Nyora meseji yako pano uye titumire kwatiri